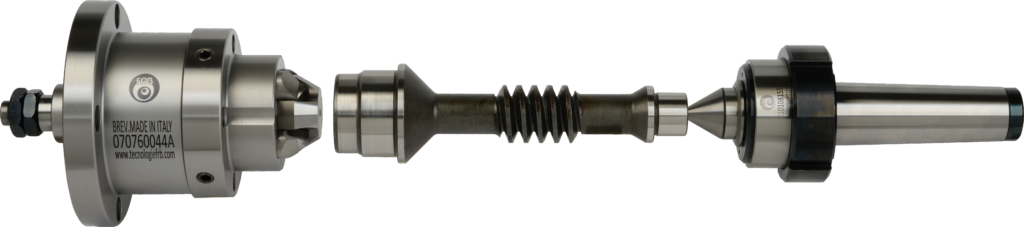

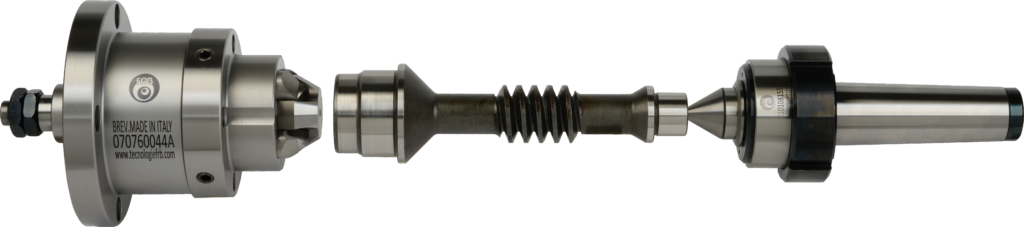

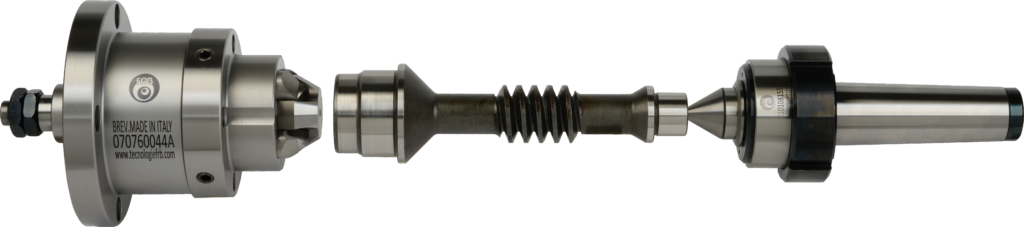

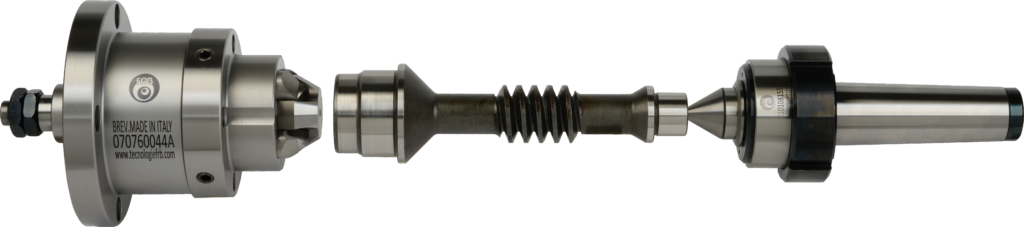

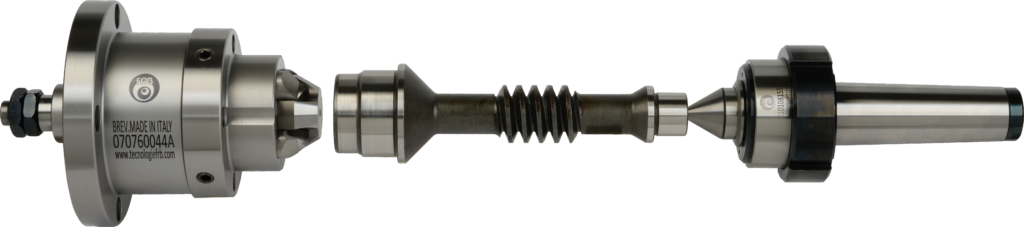

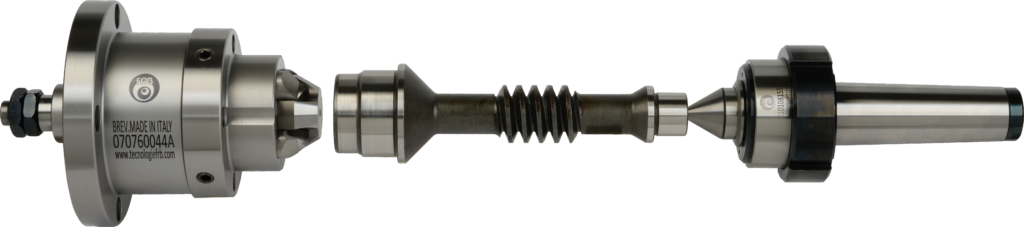

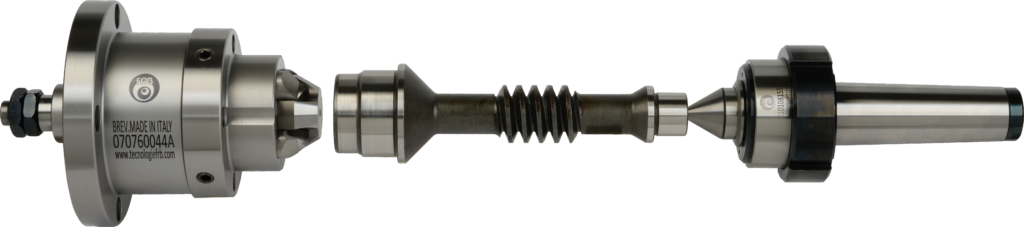

FRB Face Drivers for Gear Cutting, Turning, and Grinding

FRB Face Drivers - Models & Capacities

Our range of FRB Face Drivers is available in different capacities, allowing you to choose the perfect tool for your specific machining needs. Each face driver is designed to ensure optimum performance in gear cutting, turning, and grinding.

Our Face Driver Series

Series 6/30

- Driving Diameter

6mm-30mm (0.24 - 1.18)

- Pin Actuation

Spring or Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Turning

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 12/50

- Driving Diameter

12mm-50mm (0.47 - 1.97)

- Pin Actuation

Spring or Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Turning

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 15/55

- Driving Diameter

15mm-55mm (0.59 - 2.17)

- Pin Actuation

Spring or Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Turning

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 20/60

- Driving Diameter

20mm-60mm (0.79 - 2.36)

- Pin Actuation

Spring or Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Turning

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 20/70

- Driving Diameter

20mm-70mm (0.79 - 2.76)

- Pin Actuation

Spring or Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Turning

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 45/120

- Driving Diameter

45mm-120mm (1.77 - 4.72)

- Pin Actuation

Spring or Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Turning

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 100/220

- Driving Diameter

100mm-220mm (3.94 - 8.66)

- Pin Actuation

Spring or Mechanical

- Mounting Options

Flange

- Application

Turning

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 180/300

- Driving Diameter

180mm-300mm (7.09 - 11.81)

- Pin Actuation

Spring or Mechanical

- Mounting Options

Flange

- Application

Turning

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 7/25

- Driving Diameter

7mm-25mm (0.28" - 0.98”)

- Pin Actuation

Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Grinding

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths)

Series 15/75

- Driving Diameter

15mm-75mm (0.59" - 2.95”)

- Pin Actuation

Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Grinding

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths)

Series 20/80

- Driving Diameter

20mm-80mm (0.79" - 3.15”)

- Pin Actuation

Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Grinding

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths)

Series 20/100

- Driving Diameter

20mm-100mm (0.79" - 3.94”)

- Pin Actuation

Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Grinding

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths)

Series 45/150

- Driving Diameter

45mm-150mm (1.77" - 5.91”)

- Pin Actuation

Mechanical

- Mounting Options

Flange or Morse Taper

- Application

Grinding

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths)

Series 100/300

- Driving Diameter

100mm-300mm (3.94" - 11.81”)

- Pin Actuation

Mechanical

- Mounting Options

Flange

- Application

Grinding

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths)

Series 180/400

- Driving Diameter

180mm-400mm (7.09" - 15.75”)

- Pin Actuation

Mechanical

- Mounting Options

Flange

- Application

Grinding

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths)

Series 15/55

- Driving Diameter

15mm-55mm (0.59 - 2.17)

- Pin Actuation

Spring

- Mounting Options

Flange

- Application

Gear Cutting

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 20/70

- Driving Diameter

20mm-70mm (0.79 - 2.76)

- Pin Actuation

Spring

- Mounting Options

Flange

- Application

Gear Cutting

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Series 45/120

- Driving Diameter

45mm-120mm (1.77 - 4.72)

- Pin Actuation

Spring

- Mounting Options

Flange

- Application

Gear Cutting

Pin Specifications and Features

4 Independently compensated pins adjust up to 3mm for irregular faces

No tools required to change pins

Pins can be re-sharpened up to 3mm from original length

Variety of center point and driving pin configurations available to fit your application.

Max runout 0.02mm (8/10ths) Hydraulic, 0.05mm (2 thou) Spring

Drive Discs Fixed Teeth

- Driving Diameter

Custom for application

- Pin Actuation

Spring

- Mounting Options

Flange

- Application

Gear Cutting

Pin Specifications and Features

Fixed Teeth for gear cutting applications

Fixed Disc Positioning for Lateral Pressure and Optimal Length Tolerances

TBD

Varity of sizes and styles to meet application needs

Tbd

Precision Engineering for Versatile Applications

Each FRB Face Driver is meticulously crafted to meet the needs of a wide range of industries. Designed for durability and reliability, our face drivers excel in applications such as:

- Gear Cutting: Achieve the highest precision in gear manufacturing with our FRB Face Drivers for gear cutting, ensuring smoother operations and higher-quality finishes.

- Turning: Experience unmatched stability and precision in turning operations, even for irregular or complex geometries

- Grinding: Designed for precision grinding, our face drivers maintain the exact tolerances required in high-precision applications.

Key Benefits of FRB Face Drivers

Our FRB Face Drivers provide multiple advantages to improve your machining process:

- Adjustable Centering Mechanism: Allows for flexible part alignment, reducing setup time and increasing productivity.

- Maximum Clamping Force: Ensures secure grip, minimizing part slippage even in high-torque machining operations.

- Wear-Resistant Construction: Built with hardened materials to endure wear and tear in high-volume production environments.

- Quick Changeovers: Easily switch between different sizes and operations with minimal downtime, enhancing overall efficiency.

- Enhanced Surface Finish: Reduce chatter and vibration, ensuring superior surface finish quality for parts

Industries We Serve

FRB Face Drivers are trusted across various industries due to their versatility and precision:

- Automotive: Our face drivers are ideal for manufacturing gears, shafts, and other precision automotive components.

- Aerospace: Delivering the tight tolerances required in aerospace component production, particularly in turning and grinding.

- Machinery Manufacturing: Used in the creation of machine parts where exact measurements and reliable performance are critical.

Custom Solutions for Unique Machining Needs

At FRB America, we understand that each production environment is unique. That's why we offer custom FRB Face Drivers tailored to your specific requirements. Whether you need modifications for unique part geometries or different clamping forces, our team is ready to provide a solution that meets your needs.

Video Demo

Face Drivers in action for different applications.

Downloadable Resources

Contact Us for More Information on FRB Face Drivers

Looking to upgrade your machining capabilities? Contact us today to learn more about our FRB Face Drivers for gear cutting, turning, and grinding. Let us help you find the perfect solution for your application.